Great facelift for the air conditioning generation Ultralight 3

Konvekta pats the Ultralight series a comprehensive facelift - with new energy balance and modernized optics

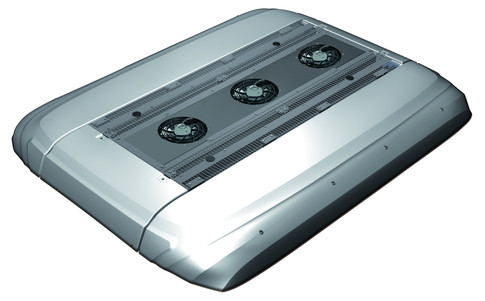

The roof compact air conditioning line series of Konvekta Ultralight (UL) built since 2008 for buses gets their second facelift. Even more consistent than the predecessor series dominates the principle of reduction. No additional volumes build up, all technical components are built into a high-compact unit. The new system comes with a significantly reduced amount of refrigerant and saves energy while improving improved performance. Even with the new Ultra Light 3, the proven specially developed high-performance material serves as the basis for receiving all components. In variant 3, the interfaces and edges were revised, which achieves even better service friendliness and a higher tightness.

More efficiency, less refrigerant

The high tightness and the insulating effect of the material reduce energy needs. Through the revision and the exchange of components and lines, the entire system requires 50% less refrigerant compared to its predecessor. The amount of the refrigerant could be significantly reduced from about 10 kg to less than 5 kg with simultaneous performance enhancement.

This is very important in this day and age as the EU has strongly regulated the use of F-gases such as R134 a. Then and the import of this refrigerant was drastically reduced. The consequences had already been clearly noticeable last year, R134 a threw itself around four to five times. Also, there was already considerable, partly weeks long delivery bottlenecks, not only on the German service market. It is all the more important that climate systems are becoming more economical and more efficient.

Modern, powerful and aerodynamic

The air conditioning series Ultralight is characterized by a state-of-the-art design. With its dynamic, sharp-cut edge curves and the puristic surfaces, it is not only for modern automobile design - but especially for functionality and aerodynamics. Also, this series is the name Ultralight program.

By further reducing weight, the further developed Ultralight 3 weighs only about 100 kilograms in the lightest version. The range of services of the UL series ranges from 24 kW to 45 kW cooling capacity and a generous heating capacity of 30 kW up to 48 kW.

Optimized service and maintenance times

With respect to the life cycle costs, the Ultralight 3 could be further optimized. So the hay parts are easier to open, as the fit of the overall construction has been revised.

The base material also prevents dust and dirt in the system. The time-saving locking function was maintained, but the plug-in sockets were improved in the hoods. Due to the predominantly helical structure in the plug-in principle and the new placement concept of the components, service and maintenance parts are very accessible.

All components can be exchanged easily and quickly. Thus, the service works with an even lower time expenditure can be realized. The system must be opened laterally, so that entering the bus roof is not necessary. All hypopers are optimally equipped with quick-release fasteners and damper brackets for a quick service.

Responsibility for the environment

The new generation Ultralight was optimized not only in terms of their technical properties and in the area of service. The commitment of Konvekta AG for the environment as well as their protection is reflected again in the UL3.

The aim of the improvements was also to develop the future climate and heating systems and all associated processes environmentally friendly and energy-efficient. Accordingly, the Facelift of the Ultralight has a clear attention was paid to components and processing methods. Thus, even with this generation, the entire system remains 100% recyclable. All stages of production were optimized environmentally friendly and energetically.

The application of environmentally friendly components and the economical use of raw materials and energy, are further positive characteristics of the system. In addition, an optimized packaging and transport system has also been developed. Reusable building blocks made of a lightweight but robust material wear the air conditioning systems and enable the simple stack of multiple systems.

This eliminates additional cardboard boxes and plastic packaging. Ultralight 3 is a technological statement for the future and saves the operators service and energy costs.

Data & facts

- Ultra-light roof top air conditioning unit for coaches, urban and intercity buses

- Weight reduction

- Reduced construction height

- Improved aerodynamics

- Thanks to high performance insulation:

- 50% less refrigerant and higher efficiency

- Insensitiveness to road conditioned vibrations

- Significantly less dust and dirt inside the unit

- Best components due to high production depth

- Service and maintenance friendly for better efficiency due to plug-in principle and new component positioning concept

- Fans with a noise emission, reduced by 5 dBA

- Completely recyclable and therefor economically valuable system