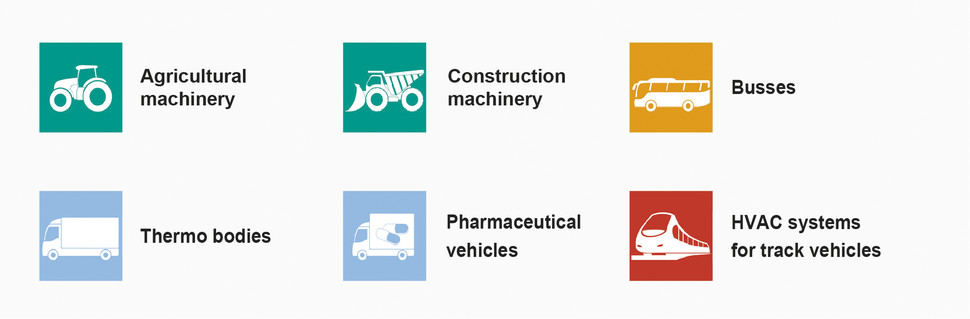

The range of services of our air conditioned hall at a glance

Our modern air conditioned hall offers the perfect environment for testing your commercial and utility vehicles and the refrigeration and heater equipment. It offers the opportunity to validate and certify the performance capability and functionality of appliances and in doing so ensures outstanding product quality.

The individual services provided by the air conditioning hall are always customised to meet your requirements. Hence, each test is preceded by a detailed discussion with our customer and service team. You will receive a validation report for documenting the results and findings after every test has been conducted.

HVAC-Validation, Component Test, Environmental Simulationen und acoustics measurement

Validation and certification:

By default, we validate and test in accordance with the following DIN standards:

- In the cabin area according to ISO 10263 and ISO 14269

- In the railways segment according to DIN EN 14813, DIN EN 13129, DIN EN 14750 and according to the TSI standard

Performance and efficiency analysis:

We measure the performance capability and functionality of your air conditioning and heating systems. For this purpose, we reproduce the most diverse temperature scenarios to ensure the performance capability and the stringent climatic comfort of your vehicle.

Cabin climate measurement:

Various test methods are deployed within the scope of climate measurement of drivers' cabins and passenger compartments in order to identify vulnerable points. With the assistance of a powerful measurement dummy, we determine, on the one hand, the cooling down speeds and parameters, which are relevant for climate comfort. On the other hand, the impact of temperature fluctuations on the indoor climate is recorded with the help of a thermal imaging camera.

Safety test:

We test the functionality of the pressure switches in the air conditioning system so that you can ensure the maximum level of safety for drivers and passengers alike.

Air output:

With the help of various measuring instruments and test benches, we are able to measure the output of blowers and fans separately. Over and above this, we are in a position to determine the air flow rate and the discharge speeds directly at the nozzles and to adjust the values, if necessary, to the optimum level.

Life cycle test of blower and fan:

Each component of your system is pushed to its limits of withstanding stress in the course of a life cycle test and subjected to a comprehensive long-term test. In this way, we can prevent potential functional losses even at the lowest level.

Imitation of extreme climatic conditions

Temperature range from winter-like -20°C up to a very hot +60°C

At the same time, you can condition a regulated relative atmospheric humidity from 30% - 80% (starting from +10°C).

You can also set up environmental simulations such as insolation (solar radiation), rain or condensed water and, in fact, snow deposits.

The high power radiators generate extreme heat with an output of up to 1500 W/m2. In this way, you can reproduce the operation of air conditioning units in very warm climatic zones. Above all, utility vehicles, which, for example, are moved on open fields or in construction pits, are frequently exposed to these conditions.

With this, the air conditioned hall offers the option of simulating climatic conditions from the most diverse zones and temperature cycles in the world.

Acoustic measurement:

In a low-reflection half space, we make measurements of the sound pressure level (dBA) of a system or individual components to determine any abnormalities or disturbing noises and to optimise the system with respect to its acoustics.

De-icing window panes:

With the help of a hot water simulator, we can simulate the process of defrosting the ice-covered wind shield in your cabin at sub-zero temperature and optimise the same based on the findings.

In this simulation, both the temperature and the flow rate can be adjusted to reproduce the most diverse test situations.