hyPowerRange - Air conditioning technology for electric buses

The task of the air conditioning of electric buses is constantly accompanied by new challenges. Nowadays, we are no longer talking about heating or air conditioning in an e-bus, but instead, the so-called ‘thermal management’, since the entire e-bus is effectively a large climatic network.

The basic challenge is that an electric drive does not generate any waste heat that can be utilised to heat up the interior space of the bus. Moreover, the batteries have to be air-conditioned in parallel so that they work for as long and as efficiently as possible.

Perspectives of the air conditioning and heating technology for e-mobility

As the pioneer of sustainable and innovative ideas, Konvekta supports several research and development projects in the field of electrification. This is where products of the next generation and new intellectual approaches are created in order to improve existing products. Konvekta relies on young, dynamic, and creative minds – all of whom work with a sense of self-responsibility, just as those involved in the ‘hyPowerRange’ project.

An innovative hybrid battery concept was developed and put on trial in the ‘hyPowerRange’ project sponsored by BMWi. The aim of the research project was to improve the factors such as range, costs, cooling and heating demand, as well as the performance of electric vehicles. Several energy storage systems – batteries – are either designed for energy or for power, but, of course, it would be optimal to combine both strengths.

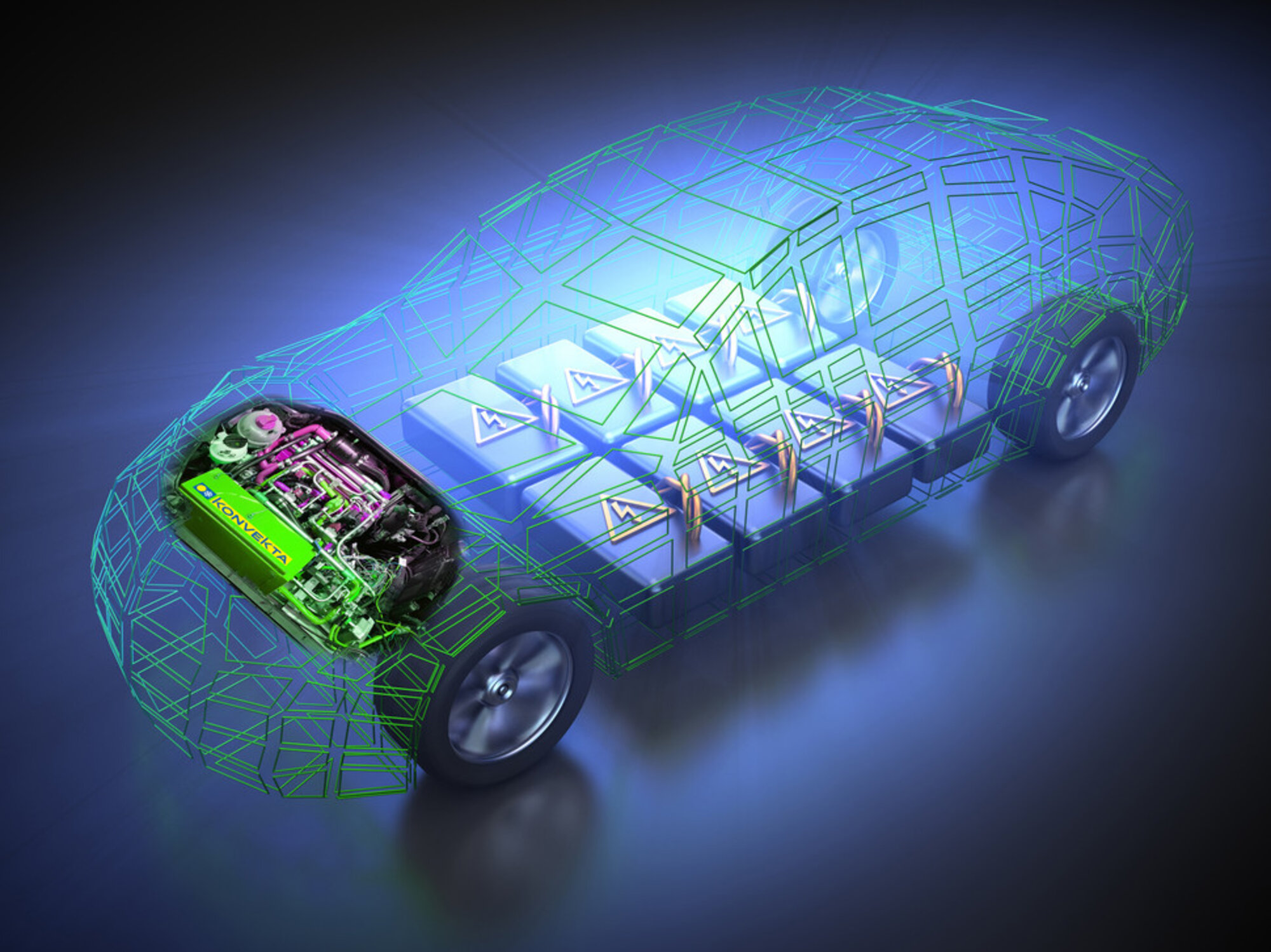

The task of the research team at Konvekta AG was to ensure constant temperature control of the battery, in order to guarantee reliable operation, consistent performance, and a high level of service life of the high-power and high-energy cells. This also included the temperature control of the vehicle interior as well as the air conditioning of electrical components such as the charger, motor, and inverter. The decision regarding the choice of vehicle fell on a passenger vehicle (Audi A3), which was converted from an internal combustion engine to an electric drive. In the process, the limited installation space available for the system combined with peak loads of up to 20 kW during battery cooling posed a special challenge.

Combination of CO2 heat pump and Heat2go

Particularly in the automotive industry, one often relies on electric heaters in order to supply the interior with warm air in the winter. This form of heating substantially lowers the range/energy consumption of an e-vehicle, since the current is drawn directly from the vehicle battery.

It is different for a system with a CO2 heat pump. The heat from the ambient air and from the heat-generating components of the vehicle (e.g. the axles) is collected by various unit and pressure statuses of the coolant. This energy is multiplied and provided for heating. Based on the experience of recent years, a new form of the CO2 heat pump has been developed, with the focus on a range-optimised battery and vehicle temperature control with thermal preconditioning from the electrical network.

The ‘hyPowerRange’ climate concept has received a new controller as well as its own sensor system. The theoretical design and development of the heat exchanger by proprietary simulation tools and validation in the test bench were undertaken at the location in Schwalmstadt of Konvekta AG.

Moreover, an advanced development of the heat accumulator from the Heat2Go project was integrated. Heat2Go is a fast-charging enabled, modular heat accumulator for electric city buses. This heat accumulator absorbs thermal energy fed to it in a small time frame by the change in the unit status from solid to liquid. The thermal energy saved there is discharged continuously during the bus travel to the vehicle’s interior as well as to secondary loads requiring a high temperature. For this purpose, the system requires no energy from the on-board batteries.

Air conditioning technology of tomorrow – ‘hyPowerRange’ is a pioneer for thermal management systems of the future for e-buses

Thanks to the ‘hyPowerRange’, we were able to gain experience and knowledge that will come in useful in the medium term in the next generation of CO2 heat pumps for e-buses. In this way, the project brought new inputs in the field of temperature management control. This means an enhancement in the efficiency of the application and the avoidance of energy losses.

With the advanced development of the heat accumulator (Heat2go), homogeneous temperature distribution could be achieved, which ensures the operation of all cells within the ‘comfort zone’ with direct connection of high-performance and high-energy cells. This ensures safe operation, consistent power, and a long service life for the battery. Moreover, by absorbing power peaks and extending the non-operative time of the compressor, you can save additional energy and conserve the compressor.

The compact installation space required a new conception of the heat exchanger that acts as a CO2 gas cooler and evaporator. The result is savings in weight of up to one-third, whilst maintaining the same level of performance.