EmCO2s 2.0 - more range for the e-bus with the new heating and air conditioning system

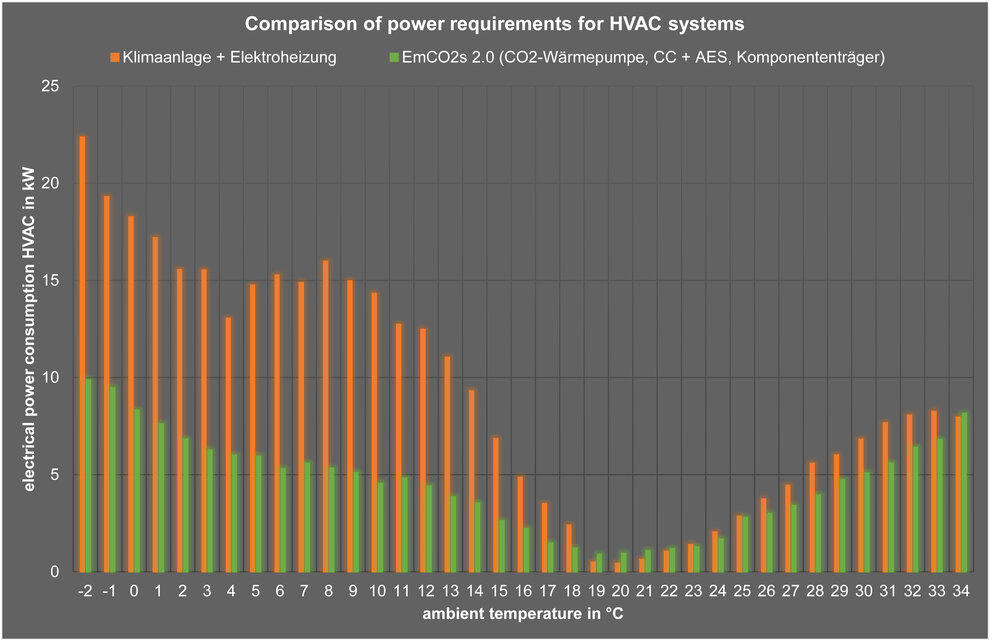

EmCO2s 2.0 (pronounced “Emcos”) is the new, emission-free heating and air conditioning system for electric buses. With the heat pump function and the alternative refrigerant CO2, the system requires significantly less energy compared to a system with an electric heater.

The technological challenges associated with the switch to electro-mobility, particularly in the area of heating and air conditioning systems, are significant. The drive of electric buses does not generate any waste heat to heat the vehicle, and the task role of air conditioning components has also grown significantly. This means that, in addition to the drive, the climate network is the main energy consumer. Therefore, electric buses require thermal management solutions that simultaneously achieve the best possible result with the least possible use of energy.

Operating an electric bus efficiently and economically in order to save costs or increase the range, is only possible with efficient heating and cooling. A conventional thermal management with additional electrical heating requires up to 50% of the energy available for an e-bus.

As much as necessary - as economically as possible

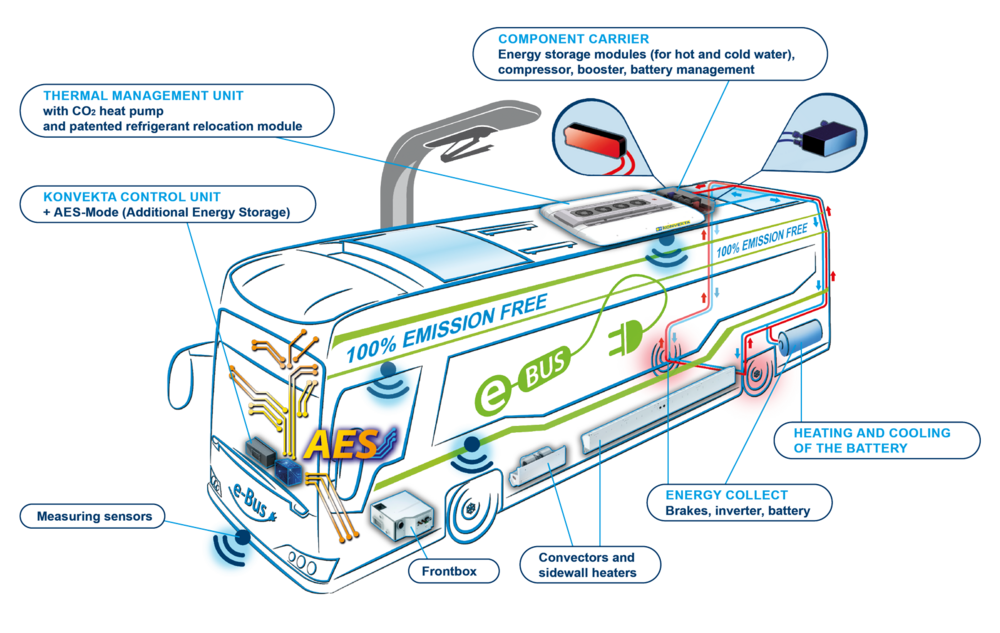

EmCO2s – Ecological Mobile CO2 System – is a climate network developed specifically for electric buses. This system offers an efficient solution for temperature control in the driver’s areas, the passenger areas and the temperature-sensitive components of the bus, such as the battery or electrical components.

The special feature of the EmCO2s System 2.0 is based on its advanced approach to thermal management. It uses a CO2 heat pump with patented refrigerant displacement technology, which is used for both heating and cooling of the passenger area and for critical components. This technology enables a significant reduction in energy consumption by obtaining up to 75% of the required heat from the ambient air. Furthermore, the EmCO2S 2.0 system collects unneeded heat in the bus and stores it in two energy carrier modules. If necessary, the heat is given back into the system, directly to the places of the bus interior where it is currently needed. This can be, for example, the waste heat from the axles or from the battery, absorbed and temporarily stored in order to later heat the passenger area of the bus.

Patented technology for improved thermal management

The patented refrigerant displacement technology consists of two circuits - one for heating and one for cooling. For example, the energy-intensive heating mode increases the demand for refrigerant. The inactive circuit - the cooling circuit - now acts as a source of resources and provides the active circuit with the missing quantity of refrigerant. This increases the performance of the system in heating mode by 10 % and reduces energy consumption. Another advantage of the refrigerant relocation is that the targeted control of the fill level means that the system always operates in an optimum range and the load on the individual components in the overall system is reduced. This extends the service life of the system and reduces maintenance costs.

Energy efficiency through Clever Control and AES mode

Furthermore, the system is made up of many specially developed components, which together result in energy savings of over 50 %. One of these components is Konvekta’s innovative “Clever Control” unit and the AES expansion module. They enable dynamic adjustment of system- performance based on current operating conditions by means of sensors within whole bus. Real-time data of passenger numbers, air quality, battery temperature, outside temperature and other influencing factors are recorded and ensure maximum energy efficiency.

For example: If there are many people in the vehicle, the interior does not need to be heated that much, because each individual person warms up the bus with its own body heat. If there are few people in the vehicle, the interior needs to be heated more. This individual control, which automatically adapts to every situation, avoids unnecessary energy losses.

Component bracket (holder)

In addition, Konvekta developed a component bracket (holder) that contains the energy component modules (for warm and cold water), the compressor, the booster and the battery temperature management. What is special about this system is the synergy of the individual elements, which together achieve an efficiency that is currently unique all over the world. Despite the resulting high savings, drivers and passengers always enjoy optimal climate comfort.

To achieve maximum efficiency, the system works with the natural refrigerant CO2 (R-744 / carbon dioxide). Compared to the traditional refrigerant (R134a) with a global warming potential (GWP) of 1.430, CO2 has a GWP of 1, making it a climate-friendly option. In addition to the ecological advantages, CO2 is characterized by its high energy efficiency, especially in colder climates - its full potential unfolds in heating mode.

Field measurement confirms: EmCO2s-System 2.0 revolutionizes energy efficiency in electric buses

In the period December 2022 to December 2023, a field measurement of two identical electric buses belonging to a transport company in central Germany impressively demonstrated the advantages of the EmCO2s system 2.0. While the bus with an EmCO2s system 2.0 only consumed 14.877 kWh, the e-bus with conventional heating and air conditioning required 35.923 kWh. Influencing factors such as drivers, operating times, etc. lead to sometimes different operating conditions, but the use of the EmCO2s system 2.0 resulted in energy savings of 21.064 kWh (at 15 ct/kWh this means a saving of € 3.160 per year / per e-bus) , which underlines the technical efficiency and thus the economic and ecological added value. This study not only showed the high efficiency of the system, but also that the desired parameters were reliably achieved in winter and summer. Drivers and passengers benefited from a consistently pleasant climate in the vehicle, which ensured well-being on all journeys.

The interaction of these technologies means that conventional heating systems, such as electric heaters or additional diesel heating, are no longer needed.

With progress in electro-mobility and innovative solutions - such as the EmCO2s System 2.0 - the vision of clean, green and quiet urban centers is taking shape.

If you only look at the consumption of the two heating systems, the EmCO2s system saves 58% of the energy compared to purely electrical heating.